| Availability: | |

|---|---|

| Quantity: | |

Bags

Description

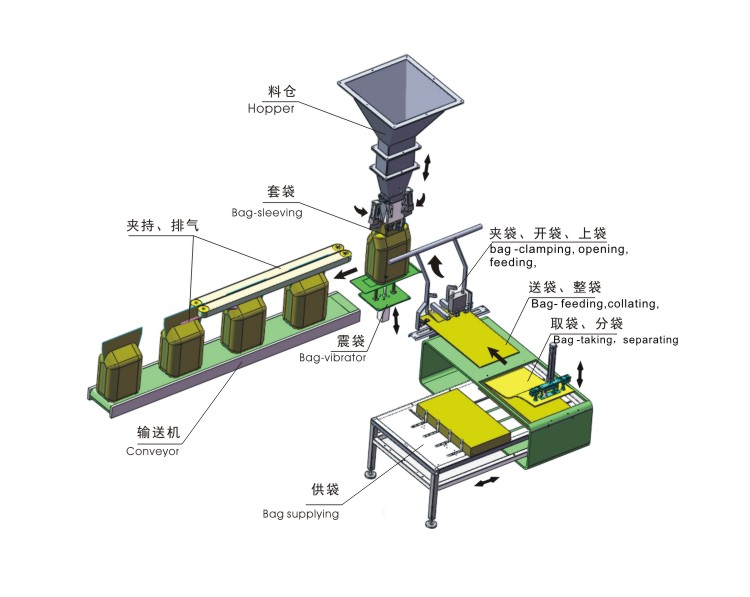

Hualian Automatic Open Mouth Bag Placer System is a combination of ZSG-1000G bag placer and FBK-332C heat sealing machine

1) ZSG-1000G bag placer

ZSG- 1000G Series Full-automatic High Speed Bag Placer is an automatic empty bag feeding and filling machine, which has the advantages of superior functions, convenient maintenance, easy operation and wide a pplication. It achieves full automatic production from operators manual bagging process to

automatically bag feeding and flling process. This machine is widely used in packaging lines of chemical raw materials, pharmaceutical raw materials, grain, fodder, food and other industries.

2) FBK-332C heat sealing machine

FBK series automatic packaging machine for sealing and stitching (here in after referred to as "sewing machine") is a product developed by our company with complete intellectual property rights. Suitable for heavy bags with packing weight of 20 ~ 50Kg; Suitable for packing single (multilayer) coated

polyethylene (PE) or polypropylene (PP) kraft paper bags, or paper plastic composite bags, or paper woven composite bags and other large bags; This series of machine can automatically complete the dedusting (optional), stitching, cutting braid, trimming bag mouth, wrapping paper tape, paper cutting tape, heat sealing, pressing and counting of the bag mouth according to the program; After packaging the packaging bag sealing performance is good, strong fastness, can achieve dustproof, moisture-proof, anti-pollution, so that the packaging materia | is properly protected.

ZSG-1000G high speed bag placer is high efficient fully auto empty bag supplying for filling machines. And differs with ZSG-300B series, ZSG-600DS series: it is higher efficiency, accurate in bag supplying. The capacity is 800-1000 bags/h. There are four servo motors for ZSG-1000G auto bag taking machine, which are for bag taking, opening, hopper lifting and bag feeding, controlled by these motors, all the process is accurate and high efficiency. The whole machine is PLC controlled to fulfill bag feeding, taking and filling processes. After placing the bag in the bag storage platform, start the machine, the bag taking mechanism would abstract the bag, the taking action is fulfilled by the bag is swinged 90 degree. Then, the process would be bag opening, sleeving and filling, in the end, the bag would be sent to the conveyor, and the bag mouth would be clamped to sealing unit.

2) Product characteristics

● Efficient and fast bag supply, strong linkage.

● Very flexible use, and can change bags of different specifica tions in a short time.

● It can automatically detect whether the bag is in place, to prevent it from being flled incorrectly.

● The whole machine's control system adopts the most advanced PLC technology to automatically complete the process of bag feeding, bagging, flling, bag venting and leveling to the sealing unit.

● The machine must form a production line together with the conveyor, and can form a fully automatic packaging production line with the processes of automatic measuring, automatic sealing, palletizing, strapping and wrapping.

Features:

√Stable performance

√Automatic fault identification

√Simple operation

√Convenient maintenance

√Easily integrated with scales

√Placing with high speeds

√Fast adjustable to different bag sizes without tools

√Fully assembled and tested before shipment.

√Available for production line

Application:

1. ZSG Series Automatic Bag Placer automatically opens and places paper, plastic and poly woven open mouth bags on to bag filling scale. High quality vacuum pumps are used to ensure the fulfillment of requirements of different types of bags.

2. It's widely used in the area of packaging production lines of chemical material, medicine material, grain, feedstuff, and foodstuff.

3. To use in the place where there is enough space, such as factory and warehouse, etc.

Parameters

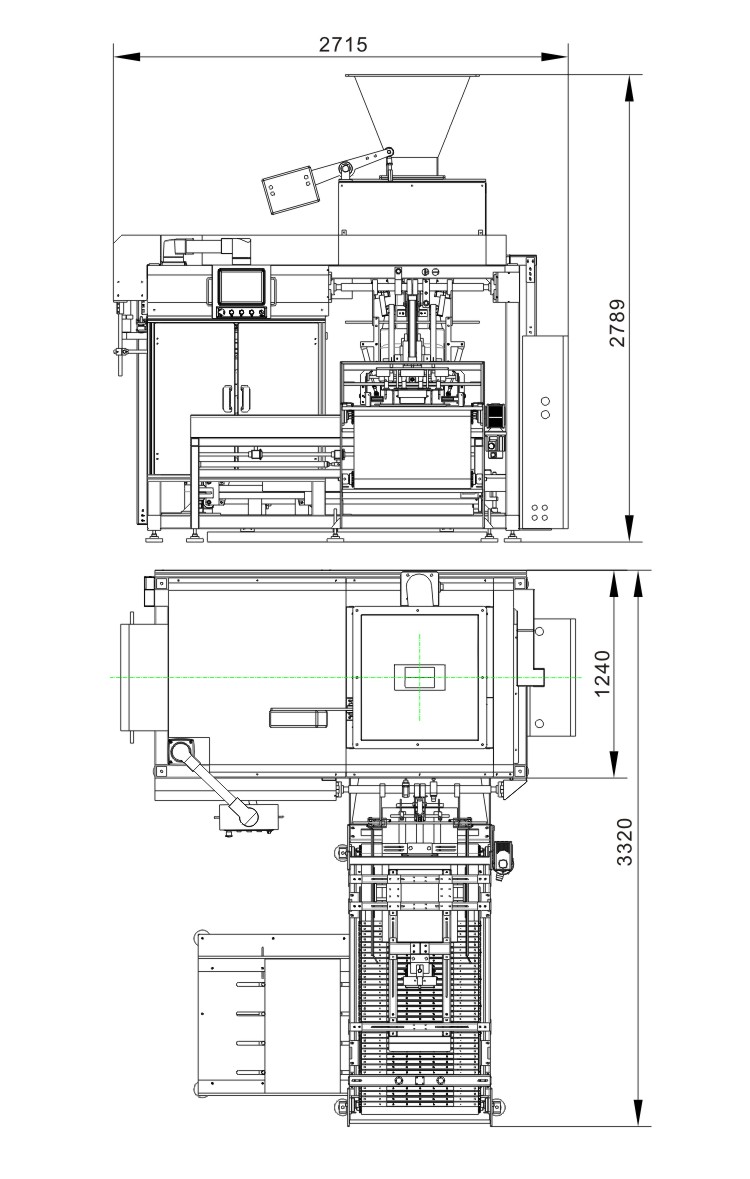

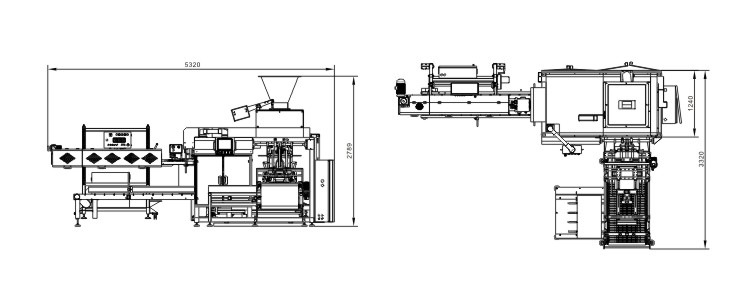

| Model | ZSG-1000G |

| Voltage (V/Hz) | (3 Phases) AC380/50 |

| Capacity (bag/h) | 800-1000 |

| Overall power (KW) | 13 |

| Air supply pressure (Mpa) | 0.4-0.6 |

| Air extracting speed (m³/h) | 22.5 |

| Weight to fill (kg) | 20-50 |

Model | FBK-332C |

Voltage(V/Hz) | AC 380/50 |

Gross Power(KW) | 6.5 |

Transmission Power(KW) | 0.75 |

Motor Power of Sewing Machine(KW) | 0.37 |

Heating Power(KW) | 0.5×10 |

Deduster Power(KW) | - |

Sealing Speed(m/min) | 8.5(Customized upper limit 11) |

Height From Sealing Center to the Floor(mm) | 750-1450 |

The minimum distance between the top of bag (mm) | 180 |

Temperature Range(℃) | 0-400 |

Air Source Pressure(Mpa) | 0.6 |

Paper tape | o |

Deduster | × |

Application | Multi-layer paper bag、paper-PE compound bag .2 in 1 or 3 in 1 bag, AL-PE inner liner bag or PE bag,etc. |

External Dimension(L×W×H)(mm) | 3030×950×1800 |

Net Weight (kg) | 600 |

Product Detail

Video