Views: 0 Author: Site Editor Publish Time: 2024-09-12 Origin: Site

Do you want to know the characteristics and advantages of kraft paper bag, plastic film bag, aluminum-plastic film bag, paper-plastic composite bag, and woven bag and other packaging bags in the process of packaging items, as well as their applications in different fields? Then we will take you to learn more!

Plastic film bags are generally made of thicker PE (polyethylene) or PP (polypropylene). Polyethylene is recognized as the best material for contact with food. The plastic structure is stable and not easily degraded by natural microorganisms. Therefore, it is widely used. It is often used in daily necessities and various foods, and can also be used in chemical raw material packaging.

1) First sewing and then wrapping with hot-melt adhesive tape

FBK-1 series bag sealing and stitching machine

2) Wrap with crepe paper tape and sewing

FBK-2 bag sealing and sewing machine series

FBS-10 bag sewing machine series

3) First folding the edge and then wrapping with hot-melt adhesive tape

FBF folding and sealing machine series

4) .Two-fold and then wrapping with hot-melt adhesive tape

FBC double folding and sealing machine series

5) .Only sewing

FBS-20C bag sewing machine series

Only Sealing

FBH heat sealing machine series

1) First sewing and then wrapping with hot-melt adhesive tape

FBHK-3 sealing and sewing machine series

2) Wrap with crepe paper tape and sewing

FBHK-2 sealing and sewing machine series

FBS-10 bag stitching machine series

3) First folding the edge and then sewing

FBHS fold and sewing machine series

FBS-20 bag sewing machine series

4) Only sewing

FBS-20C bag sewing machine series

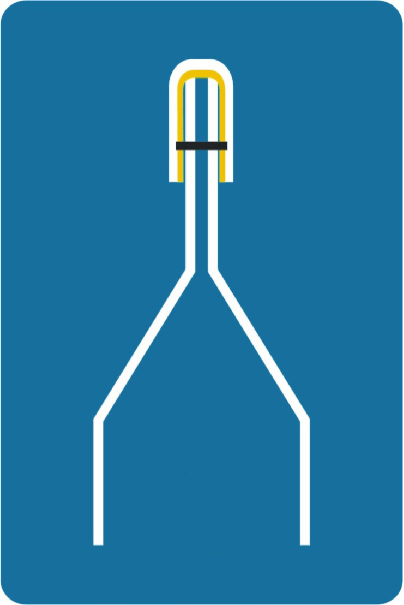

Tongue folded edge sealed

FBP fold and pinch sealer machine series

First, you need to understand the manufacturers of different large bag machines and the cases of packaging solutions they have provided in the past to determine whether they have enough experience in this field. Check whether the manufacturer has a complete R&D and after-sales team to provide timely assistance and support.

During the communication, you need to check whether the merchant can provide professional packaging knowledge and confirm whether the packaging effect you want can be achieved. In addition, whether the supplier has enough patience to help you keep trying and testing the packaging effect of the machine.

After understanding the manufacturer, you need to clarify your budget, how to purchase a large bag machine suitable for you within the budget, and consider the production needs of your own factory, how much capacity of the machine is needed, whether it needs to be equipped with a production line, and what related projects need to be customized. Provide these to your manufacturer one by one.

1. What's the materials you need to pack?

2. Check the packaging materials you need: plastic film bags, aluminum-plastic film bags, kraft paper bags, paper-plastic composite bags or woven bags.

3. Provide the thickness of the packaging bag: if it is a film bag, you need to know how thick the bag is; if it is a paper bag, you also need to know how many layers it has.

4. Provide the size of the packaging bag: how long and how wide it is?

5. Which bag opening form you want: flat bag, M-fold bag or tongue bag. (Big bag packaging machine is not suitable for valve bags)

6. How much weight do you need to pack the material: generally 10 to 50KG.

7. The form of sealing required: generally the same as the bottom sealing form of the bag.

8. Specify the reserved bag opening margin: that is the minimum height from the material to the bag opening after the packaging bag is loaded with the material.

9. What is the sealing speed you need?

Only by providing more detailed packaging information can we provide you with a heavy duty bag sealing machine that suits your needs! Please let us know your requirements without hesitation, and we can provide full customization services!

Does your machine have a bag mouth cleaning function?

Yes, our bag mouth dust removal function is to achieve this function

Do you have a conveyor?

Yes, we generally recommend customers to configure a 5-meter belt conveyor (recommended to use 0.75KW or 1.5KW variable frequency speed regulation)

Can the material only be 180mm away from the bag mouth?

Yes, it is a structural problem

What brand of sewing machine do you use?

Generally NEWLONG, DS-7C is recommended